Our inspection ability has constantly evolved and the company’s know-how is specialized in a whole variety of activities. We understand the need to use different technologies to find the best solution in each sector, therefore we defined three ranges of techniques to maximize the outcome.

PROPRIETARY SOLUTIONS

When existing NDI technologies are insufficient, intelligence and creativity make the difference. An appropriate combination of different procedures and technologies, the development of high performing proprietary software: non-destructive inspections for those who require extraordinary levels of analytical performance.

PHASEOGRAPHY

The non-destructive inspection we call “phaseography” (deriving from “ultrasonic phased array” and “ active thermography”) actually consists in the combination of these two technologies: active pulsed thermography and advanced ultrasonics. This is a test conceived for the analysis of structures in carbon fiber reinforced advanced composite materials. We have managed to develop it thanks to our experience in racing applications, and have used it for the first time for a customer operating in the MotoGP industry.

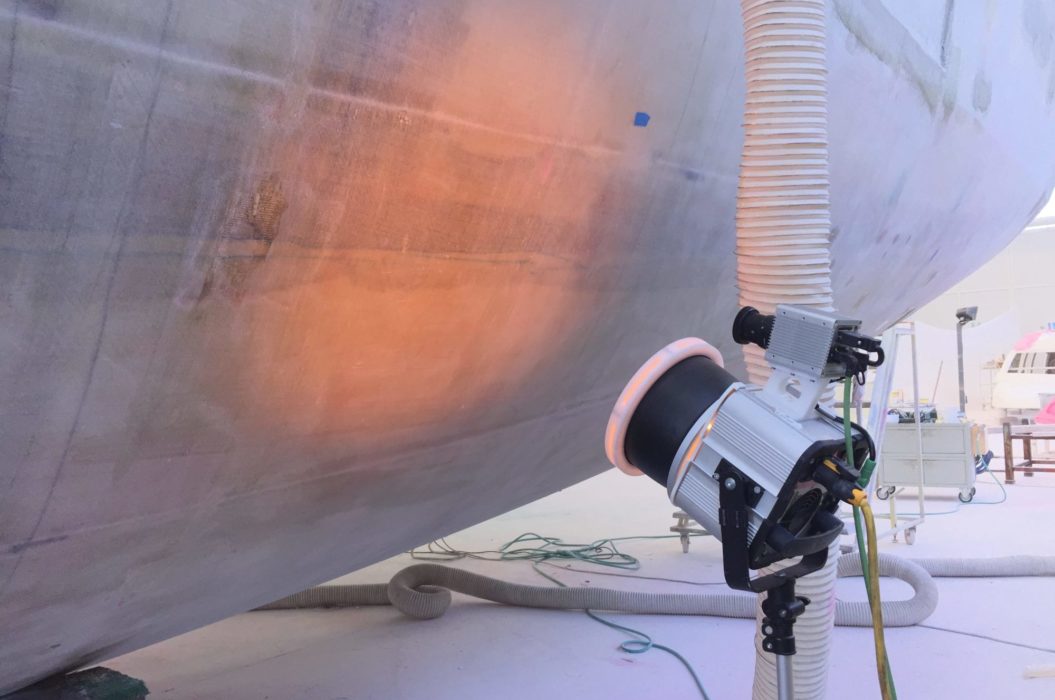

THERMOSONICS

What we call “thermosonics” is an NDI methodology we have developed for the diagnostics of glass fiber reinforced composite materials. For this reason, it has proven to be a state-of-the-art technology for the marine industry. It is fruit of a combination of transient thermography and the conventional ultrasonic methods. The synthesis of these two technologies exponentially increases the accuracy and speed of the ndi inspection, which would otherwise be limited – in practice – to a grid checks.

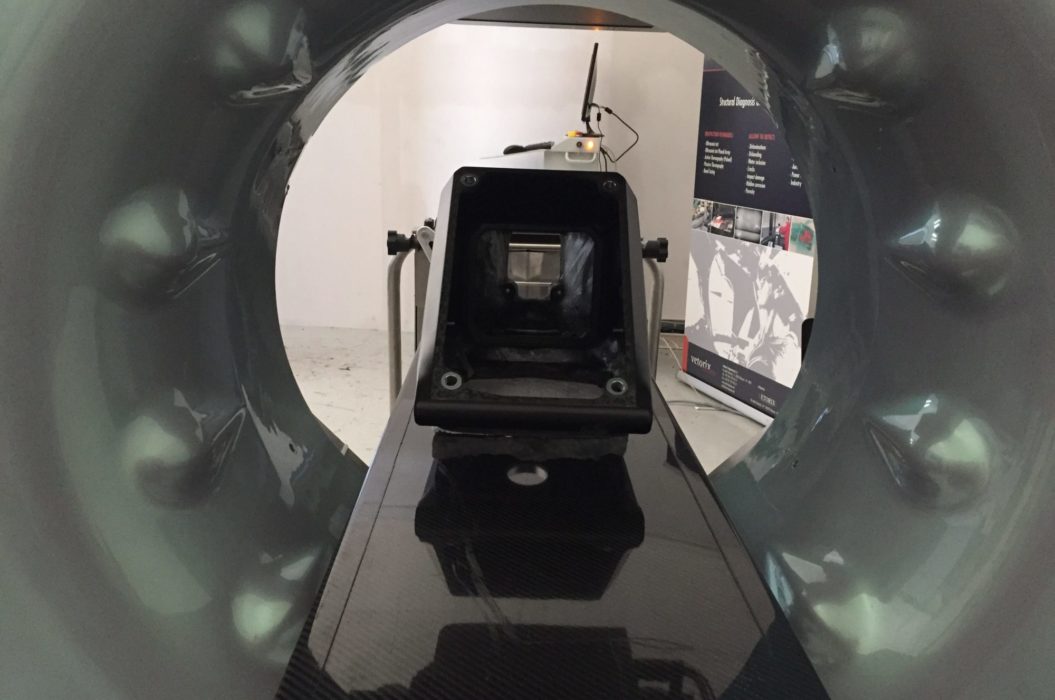

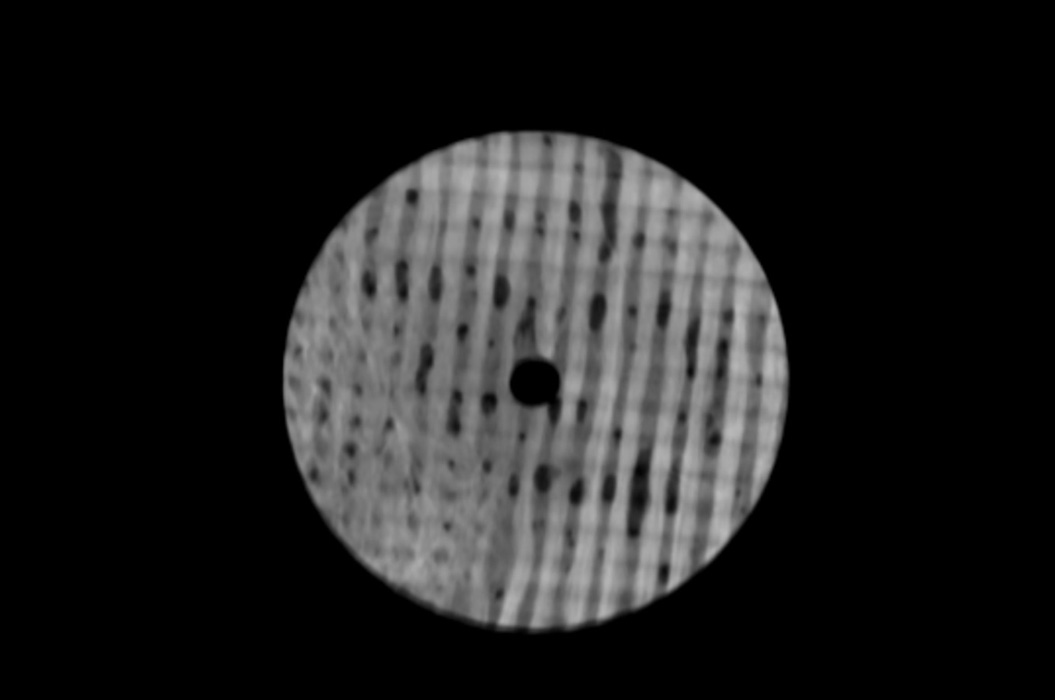

COMPUTED AXIAL TOMOGRAPHY

Computed tomography (CT), is a technology used on the industrial market. However, the instrumentation in our laboratories is unique in two ways. Firstly, it is a proprietary software developed in collaboration with computed tomography experts operating in the medical field (on the cutting edge of this technology). Secondly, a particular architecture of the device (Gantry architecture) makes it possible to inspect objects of remarkable dimensions (the length of the target structure being potentially infinite).

ADVANCED TECHNOLOGIES

The most sophisticated sensors, the most powerful software, the most innovative devices and the most qualified technical staff: this is what we mean by non-destructive inspections with state-of-the-art technologies. The result? Structural analyses whose extremely elevated accuracy and efficiency are guaranteed.

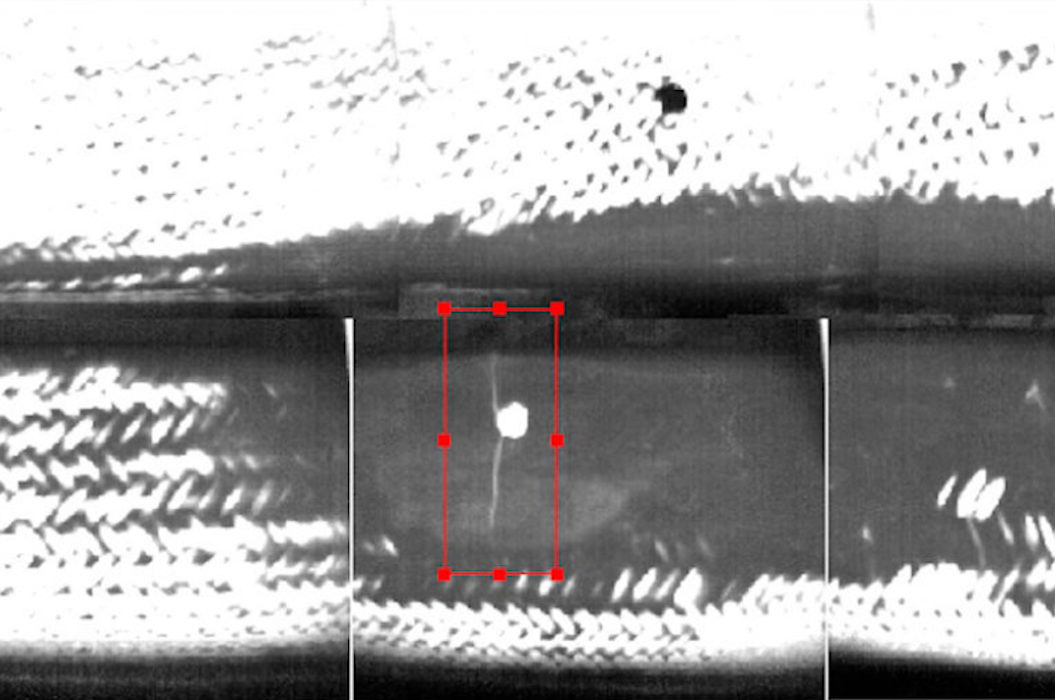

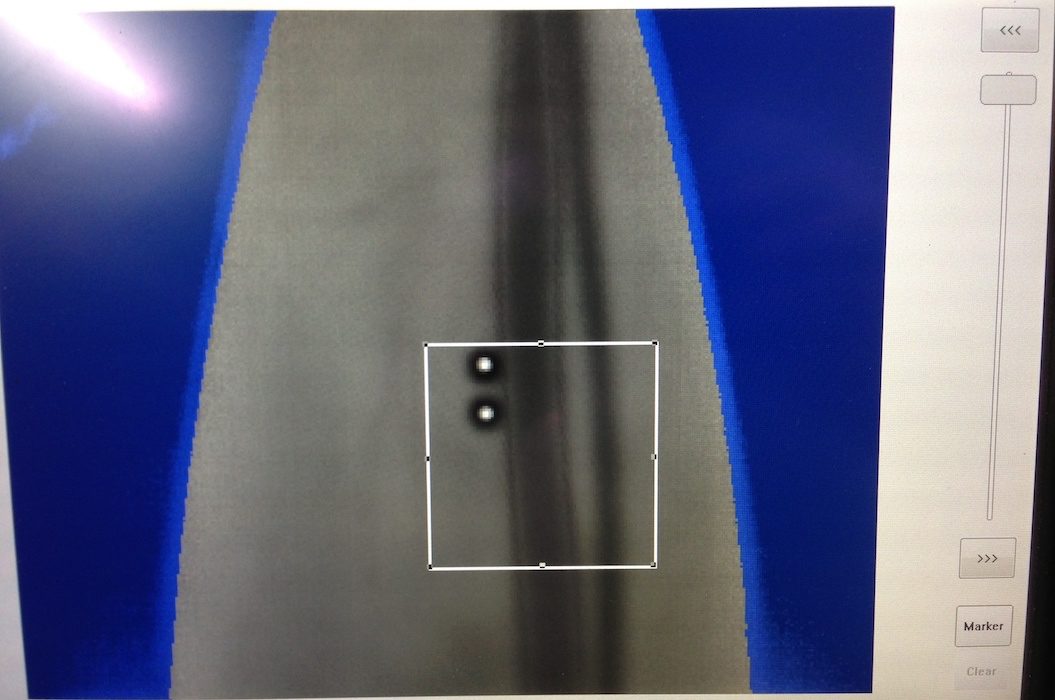

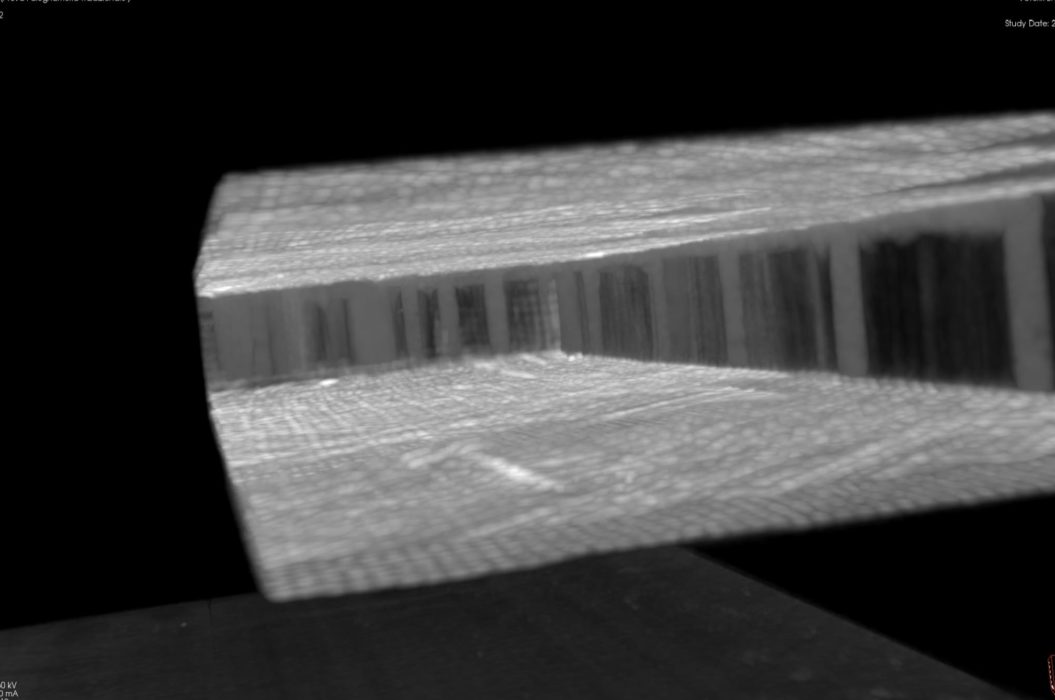

ULTRASOUND PHASED ARRAY

The non-destructive inspection method for the volumetric analysis of composite materials known as “advanced ultrasonics” is, to all effects and purposes, a further development of the analogous conventional technology, in which the detection sensors are multiplied. With this diagnostic method, not just one but sixty-four piezoelectric crystals generate a wave front within the object being inspected. Result? A more complete structural analysis and a more detailed image of a wider area, which may be viewed and recorded by cross section (sector scan) or from above (C-Scan).

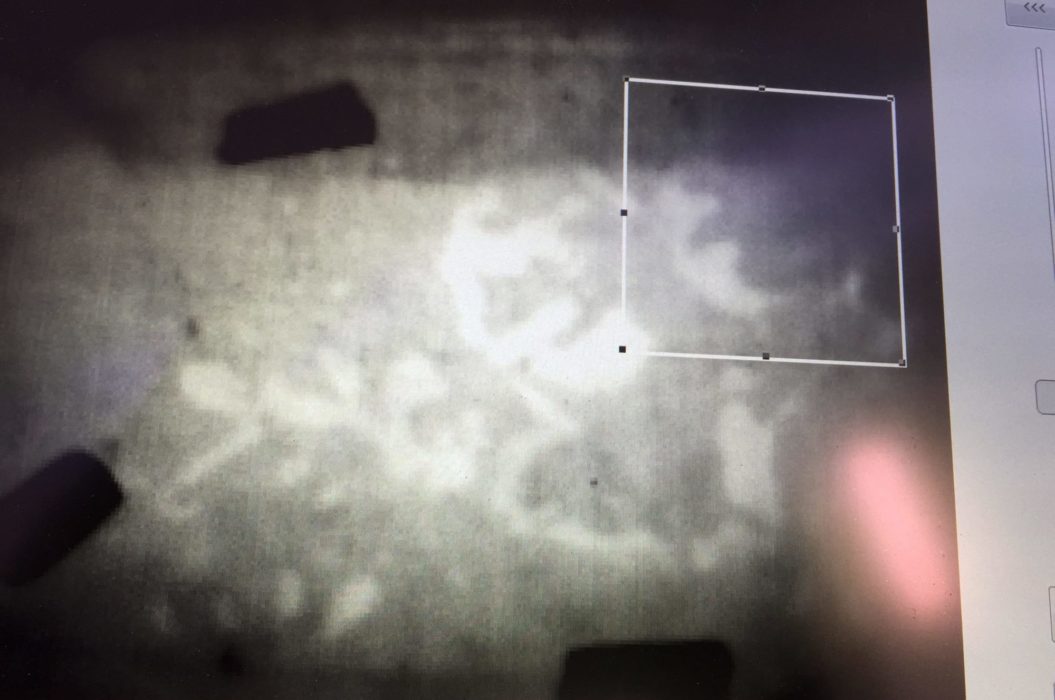

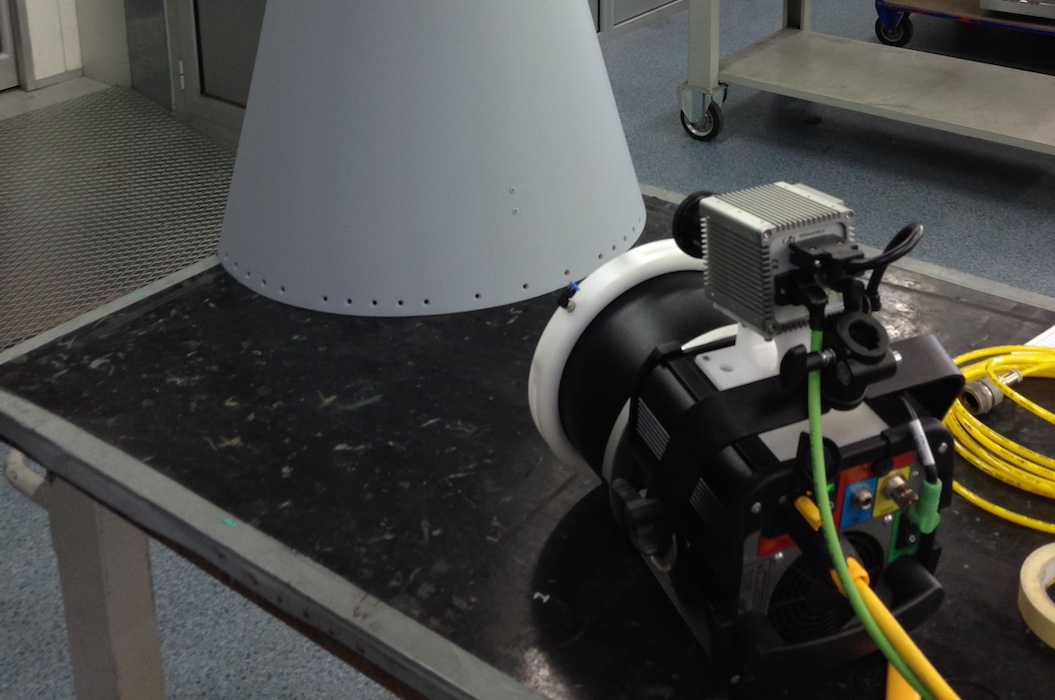

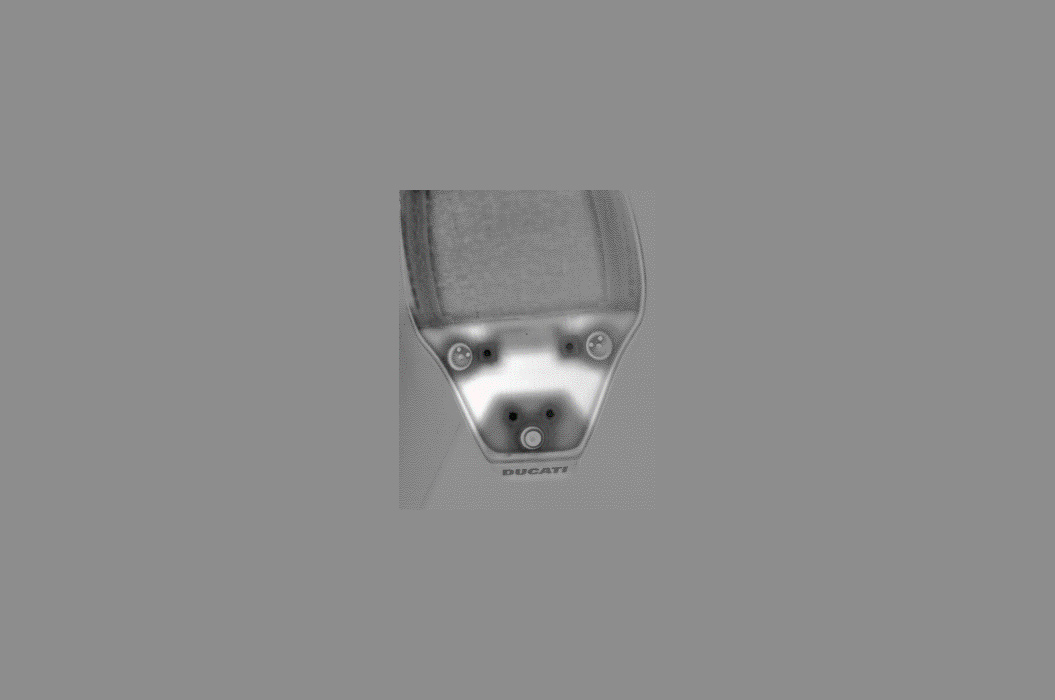

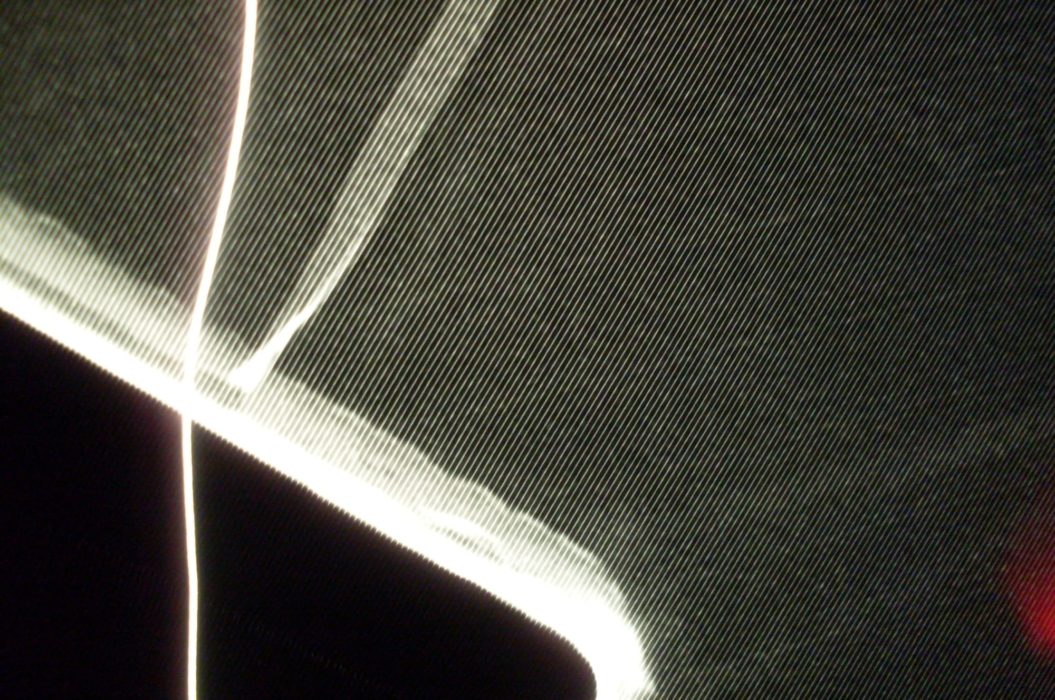

TRANSIENT THERMOGRAPHY

Active thermography is a more sophisticated NDI technique than conventional thermography. In this case, the surface to be analyzed, whether in carbon or fiberglass, is thermally stimulated by a heating system. This “activates “ any thermal anomalies and evidences both internal and surface discontinuities. Our specialized technicians, thanks to their specific training and experience in the field, are able to analyze and interpret the data produced by a special software.

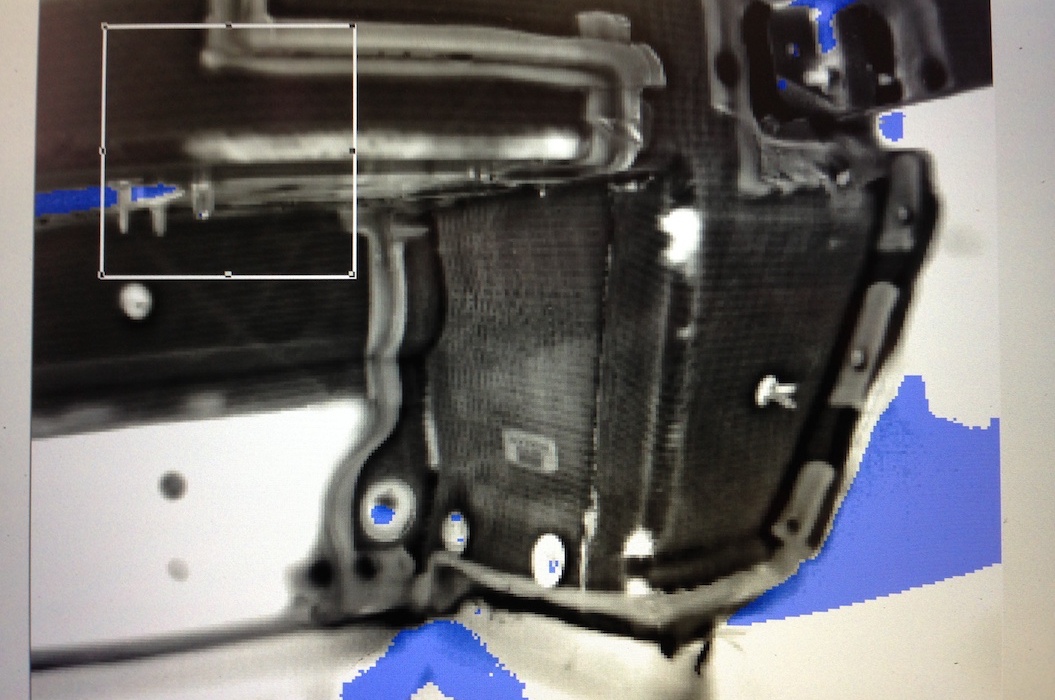

DIGITAL RADIOGRAPHY

Digital Radiology represents the technological evolution of conventional radiography. It is one of the non-destructive inspections in which digital tools are placed at the service of image diagnostics, for structural analyses that are flexible and high performing. The results of the radiographic exam are directly acquired in a digital form. By exploiting the potentials of hardware and software, digital radiography makes the viewing, filing and reprocessing of images faster and easier than any analogous analogical technique.

CONVENTIONAL TECHNOLOGIES

1983: the year in which Microsoft Word, the world’s most popular word processing program, first appeared, we started to work in the ambit of non-destructive inspections. We have acquired 35 years’ experience in NDI thanks to consolidated technologies.

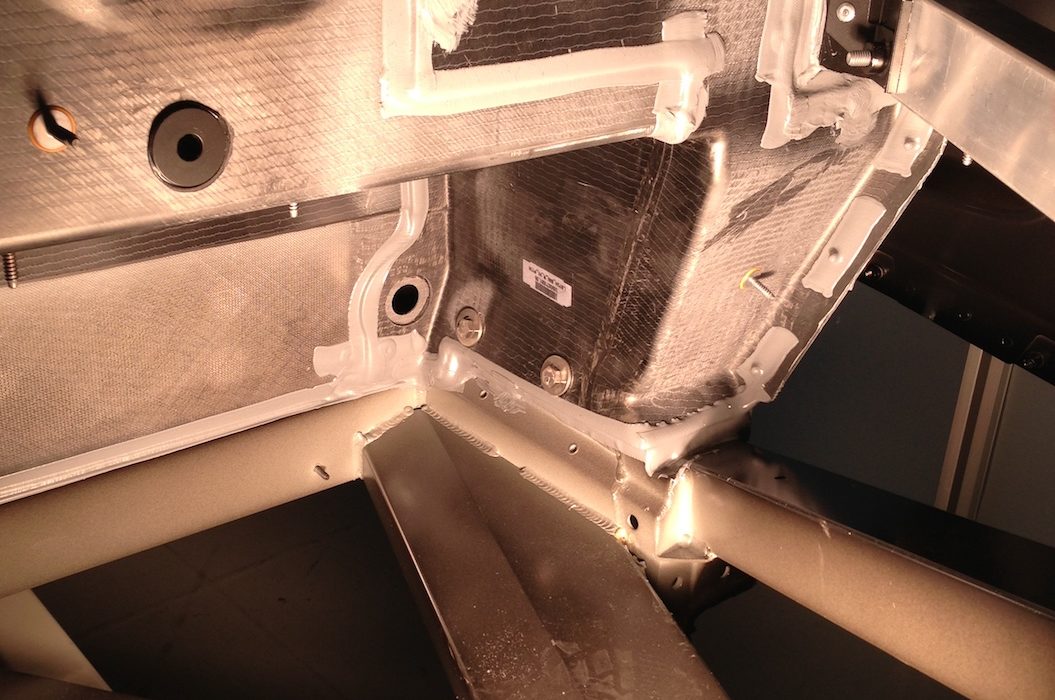

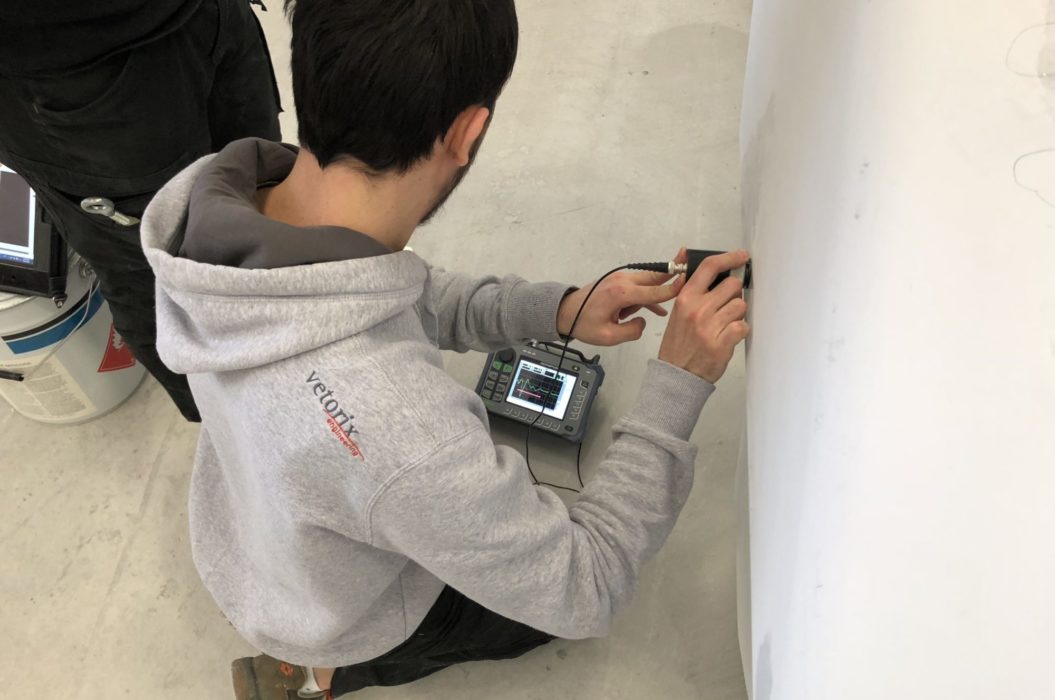

ULTRASONIC TESTING

Ultrasonic inspection is a non-destructive inspection method enabling the entire volume of an object to be structurally analyzed. It exploits the sound wave transmission properties of materials. An ultrasonic beam is projected inside the object being examined to evidence any discontinuity. The probe frequency is adequately calibrated according to the material and thickness being inspected. Our ultrasonic equipment is extremely high performing when used with composite materials, especially those in carbon fiber and fiberglass.

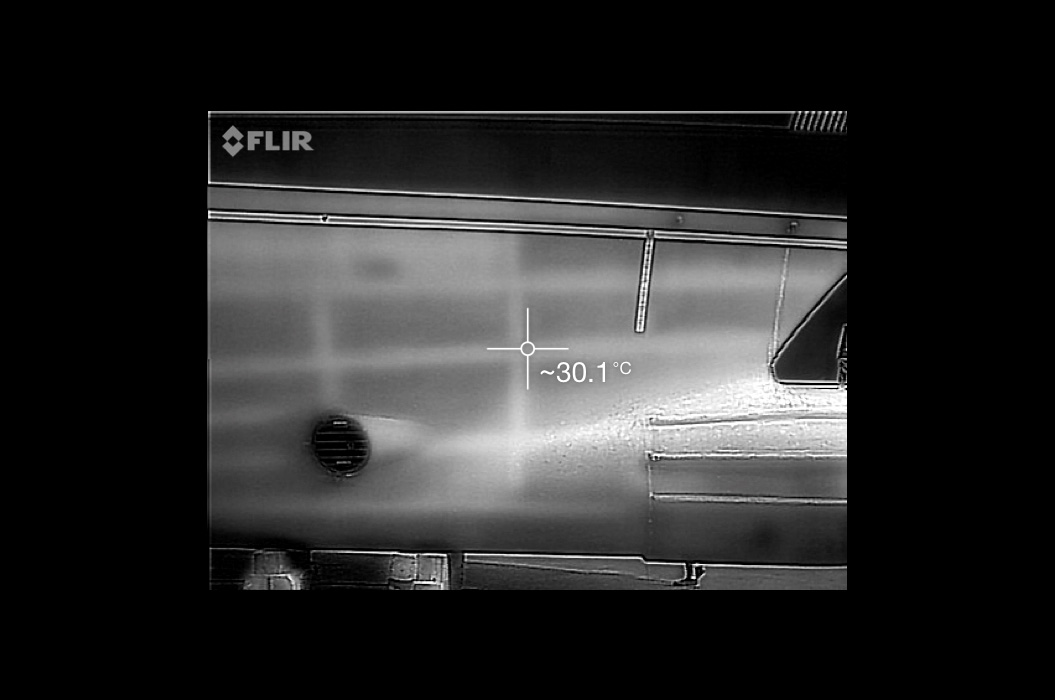

INFRARED THERMOGRAPHY

Passive thermography is a non-destructive inspection system that analyzes the temperature of an object to evidence any flaws. By means of an infrared camera, the thermal image of the object’s surface is recorded. The differences in temperature are emphasized by different colors. Specialized technicians are able to read and interpret this thermal map whose analysis reveals any anomalies and discontinuities without having to physically dissect the object.

RADIOGRAPHY

Radiography is a non-destructive inspection method enabling the volumetric inspection of an object. A beam of X-rays is projected towards the object being inspected and impressed on a film, which shows a negative image of the structure. Our specialized technicians are able to interpret the results of a radiography and identify the size, position on the X and Y axes and (if possible) the entity of any discontinuity. In our laboratories, we are able to inspect objects in carbon fiber and fiberglass of a thickness up to 300 mm.

OTHER METHODS

In order to improve the results of technologies used for NDI, it is useful at times to integrate them with other diagnostic methods, of a conventional or advanced type. We are able to determine and recommend the best possible combinations of analyses to achieve results of the highest quality. The integration of multiple methods is particularly useful for optimizing the available time and budget.